Pipe Recovery Services

the Premier Pipe Recovery

Dialog Wireline Services is the Premier Pipe Recovery in the Oil and Gas industry. Dialog also provides additional services and solutions for complicated and challenging well bore issues. Stuck pipe is one of the critical challenges in a well. It causes costly delays in drilling operations, workover AFE’s and increases downtime and production expense. These delays equate to lost productions and demands more or your resources with personnel to get your project back on track. The pipe recovery process starts with finding out the specific nature of the problem after consulting with your representative thus understanding all downhole conditions that exist. We then formulate a strategy determining what specific tools that need to be deployed that will best result in removing the pipe and BHA’s the specific problematic locations using a free point tool or stuck pipe log. Fishing tools are then deployed to extricate the pipe from the downhole fish. Dialog utilizes the freepoint tool to find the initial stuck point. A stuck pipe log can be deployed to find additional stuck points if deemed necessary. This data can be used to help determine the most time and cost-effective plan to free the stuck pipe. The stuck pipe log can determine where the pipe is free and where it is stuck. This log compliments the free point evaluation as the log tracks multiple stuck point locations versus only the shallowest point. The log data will help in deciding the best course of action to save you time and money in lost production and associated expenses. Dialog’s methods used in freeing stuck pipe include backing off and cutting. Backing off is a process where the threading is unscrewed at a predetermined wellbore depth using weight and torque. The cutting of tubulars can be done with chemical or explosive cutters. It is imperative to back off or cut where the pipe is free to ensure that tubulars and BHA’s are recovered. After the free pipe has been removed from wellbore, fishing tools can be deployed to retrieve the rest of the assembly. The recovery procedure can benefit you during Plugging and Abandoning (P & A) operations in removing installed pipe that’s no longer needed. The recovered tubulars can then be reused or sold by your company. The entire recovery process will be seamless, and you will have peace of mind knowing that Dialog Wireline Services has industry leading experience, knowledge and the most advanced tool to perform and provide a resolution for your company, thus saving your resources for other high value tasks.

- We answer your call 24/7, and you will be connected with a Dialog professional to provide solutions tailored to your specific needs and wellbore conditions.

- Dialog personnel have experience in all types of tubulars including drill pipe, casing, coil tubing and tubing.

- Dialog can provide pricing to insure your AFE comes in on budget and on time!

- We have experience in deviated, horizontal, high temperature/high pressure as well as sour gas wells.

- Dialog has the latest technology as well as fit for purpose equipment to provide the highest quality pipe recovery services.

- We have internally trained personnel that understand the fluid and challenging downhole conditions that exist in your well.

We thank you for allowing Dialog Wireline Services to be your solutions provider for all of your stuck pipe challenges for your company, and we look forward to working directly with you on your next issue!

Backoff

(String Shot)

The Dialog backoff service applies left-hand torque in the pipe while the string shot is detonated.

Chemical Cutter

The Dialog chemical cutter service is used commonly in wireline pipe recovery operations. It cuts through coiled tubing, tubing, casing, or drill pipe with a cut that does not have a flare and does not distort the pipe ID or OD.

Free Point

The Dialog free point service uses an electromechanical tool designed to measure the amount of torque and/or stretch of a given length of tubing, coiled tubing, drill pipe or casing.

GYRO/WHIP

Gyro/Whip stock Orientation Dialog can help get your drilling back on schedule due to the orientation of the whipstock when using the Gyro tool during sidetracking. This service insures that interference of MWD doesn’t occur and wellbore trajectory stays within your parameters.

Scientific Drilling has dedicated over 30 years to delivering precision gyro surveying - ensuring safe, efficient operations and optimal wellbore placement.

Radial Cutting Torch (RCT)

Dialog is one of a select few companies licensed by MCR Oil Tools to run their patented Radial cutting torch.

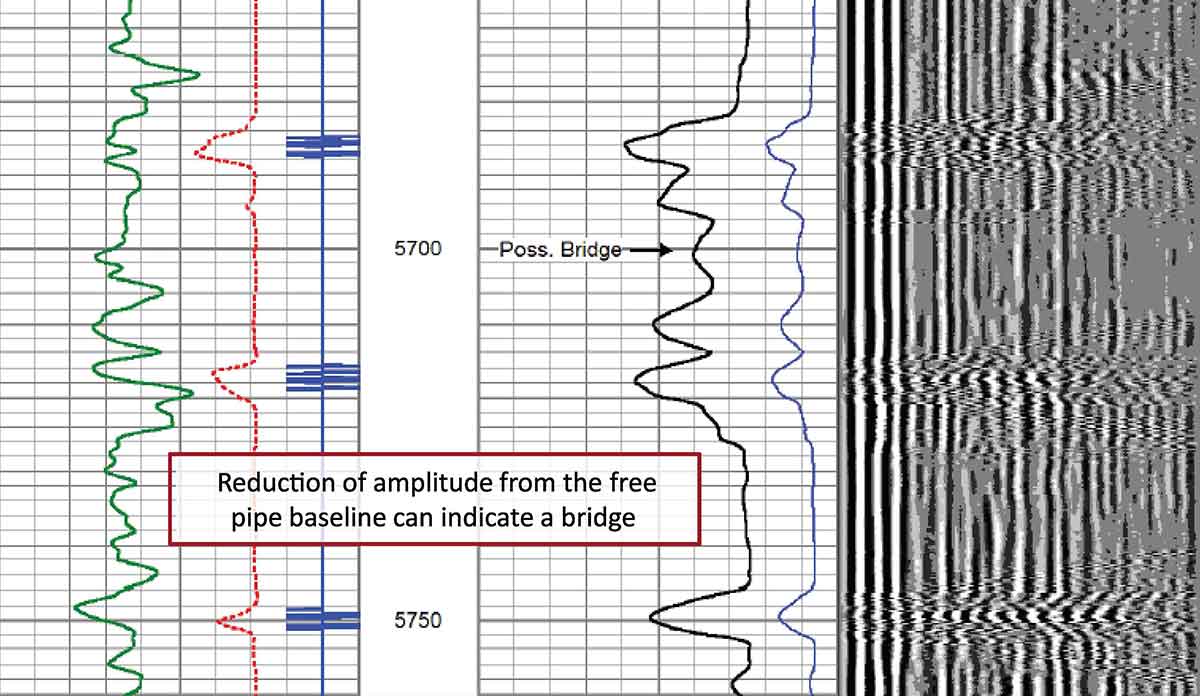

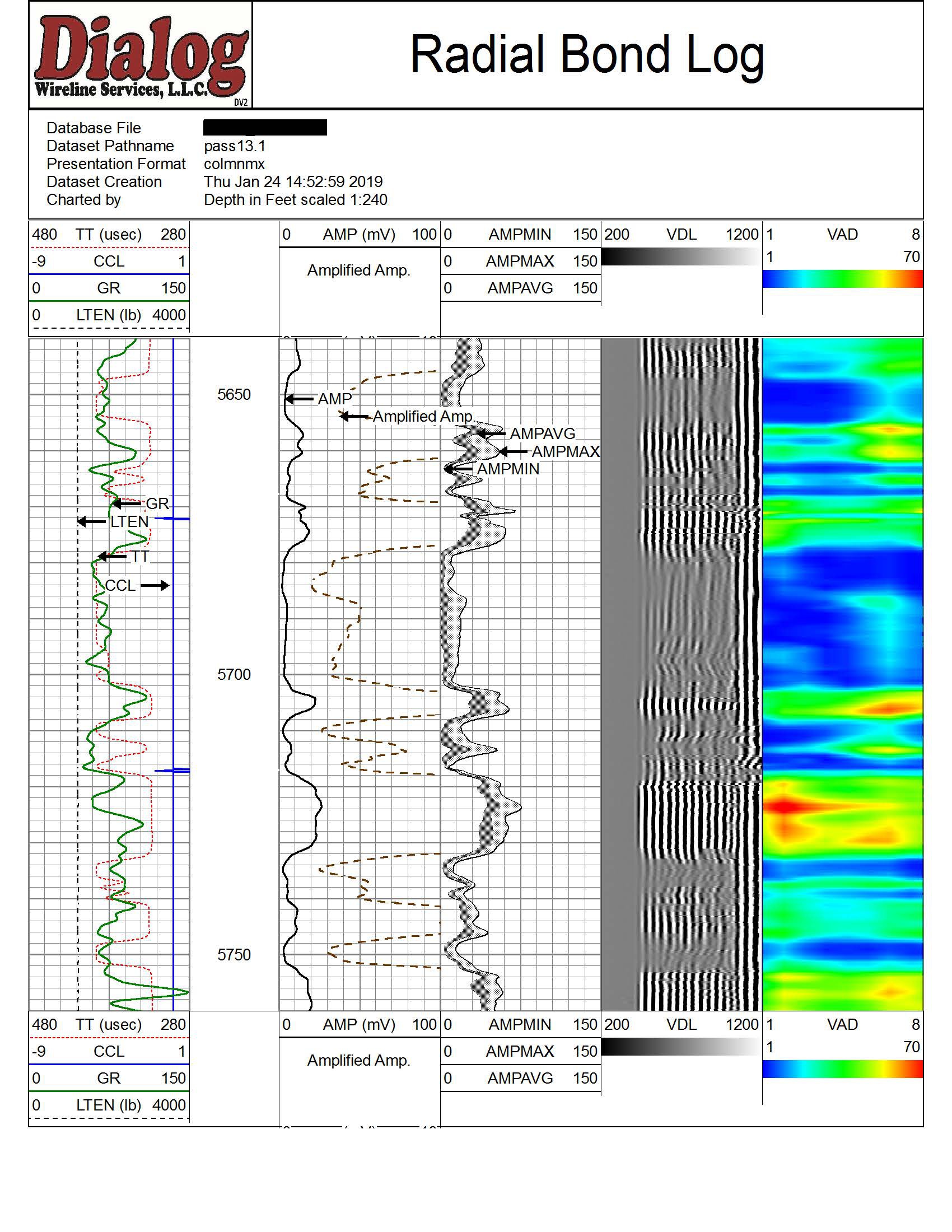

Stuck Pipe Log

The Dialog stuck pipe log service uses a sonic measurement to provide an evaluation of a stuck pipe string. This service can be performed through drill pipe, casing or tubing to identify problem areas. Similar to conventional cement bond log measurement, high amplitude measurements indicate free pipe and low amplitude measurements indicate stuck pipe.

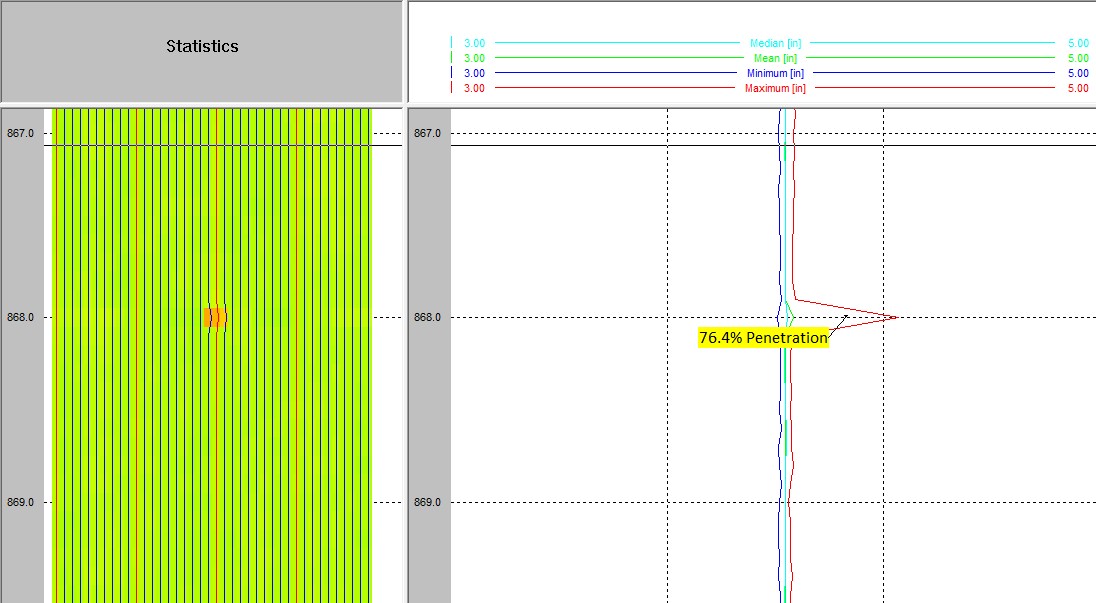

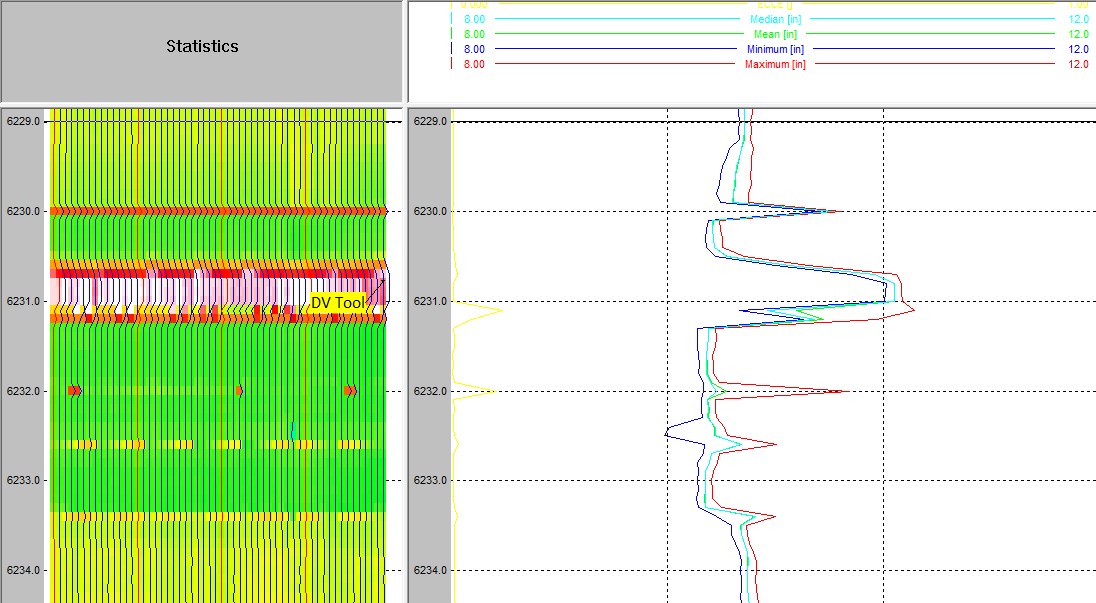

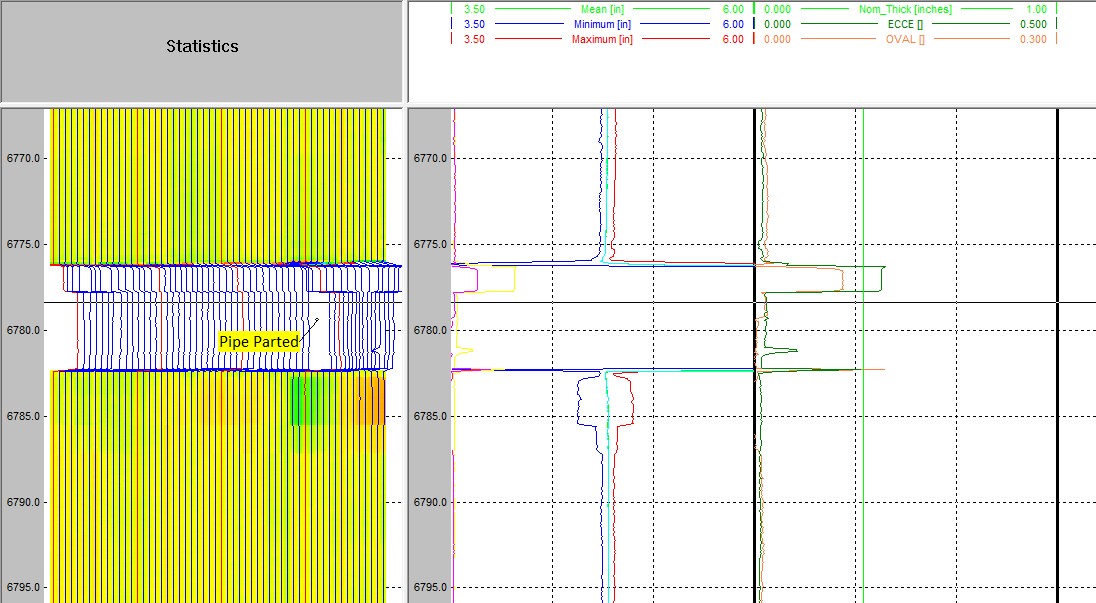

40 Arm Casing Caliper

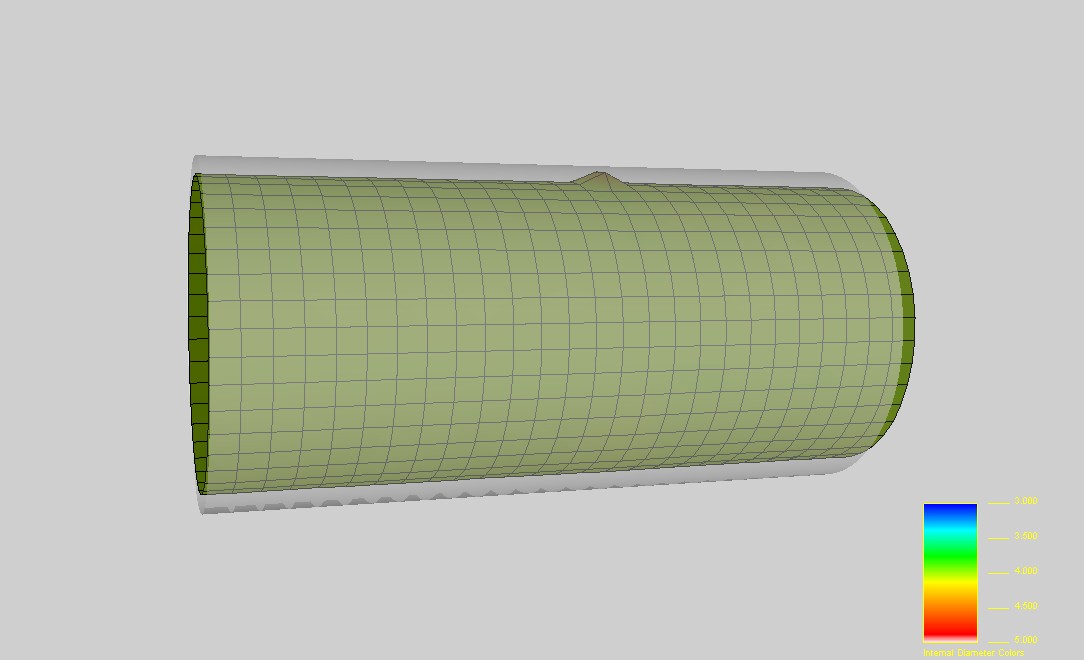

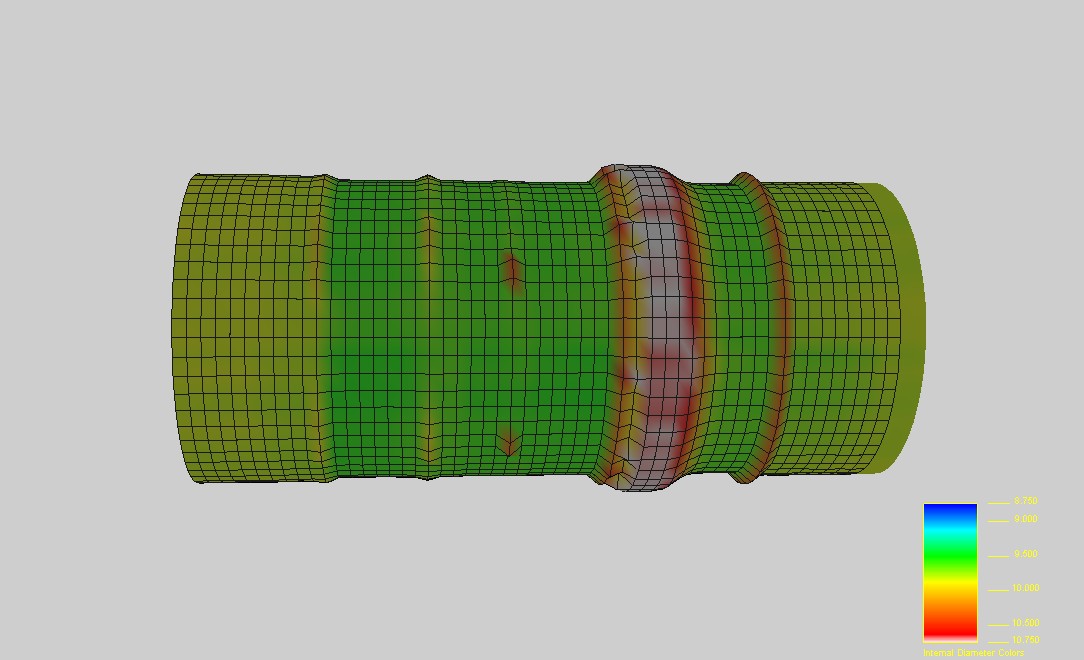

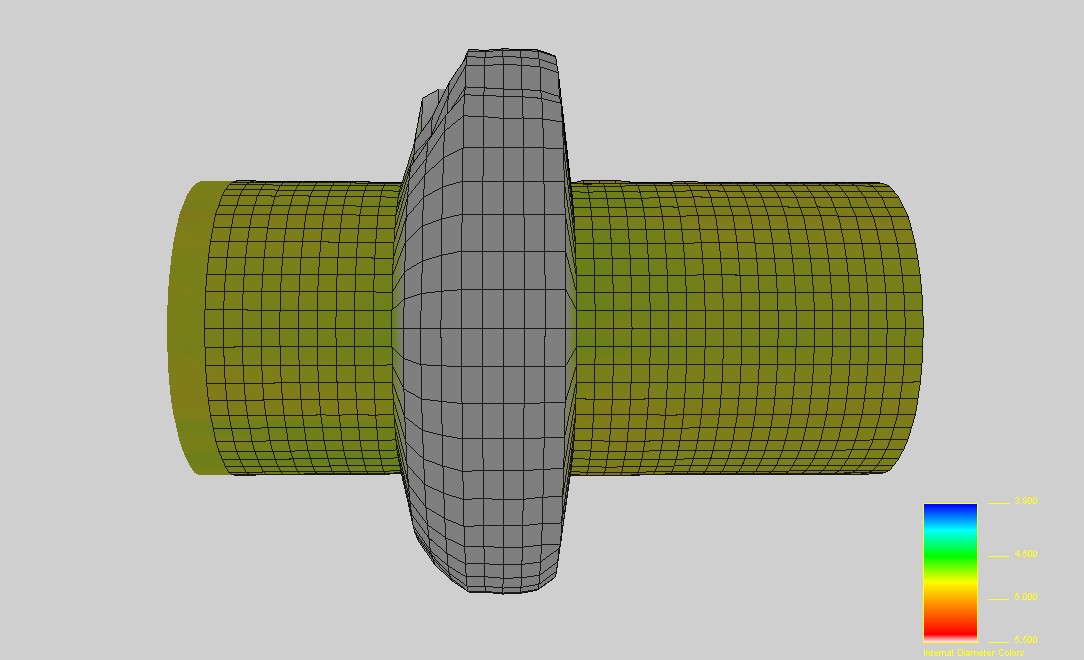

The 40 Arm Caliper is a mechanical downhole well logging tool. The primary function is to detect the deformation, bending, fracture, perforation and inner wall corrosion of casing with caliper fingers that are in close contact with the inner wall of the casing. Each caliper finger is connected to an independent non-contact displacement transducer that features small sizes, long service life, and high measurement accuracy. It measures pipe ID from 3.11” to 8.25”. After data is processed by the computer software, the diagram of borehole inner diameter and a 3-D image of the casing are created to intuitively demonstrate the damage details of downhole casing.

56 Arm Casing Caliper

The 56 Arm Caliper is a mechanical downhole well logging tool. The primary function is to detect the deformation, bending, fracture, perforation and inner wall corrosion of casing with 56 caliper fingers that are in close contact with the inner wall of the casing. Each caliper finger is connected to an independent non-contact displacement transducer that features small sizes, long service life, and high measurement accuracy. It measures pipe ID from 3.94” to 9.625” and out to 13.625” with extended length fingers. After data is processed by the computer software, the diagram of borehole inner diameter and a 3-D image of the casing are created to intuitively demonstrate the damage details of downhole casing.

Cement / Radial bond log

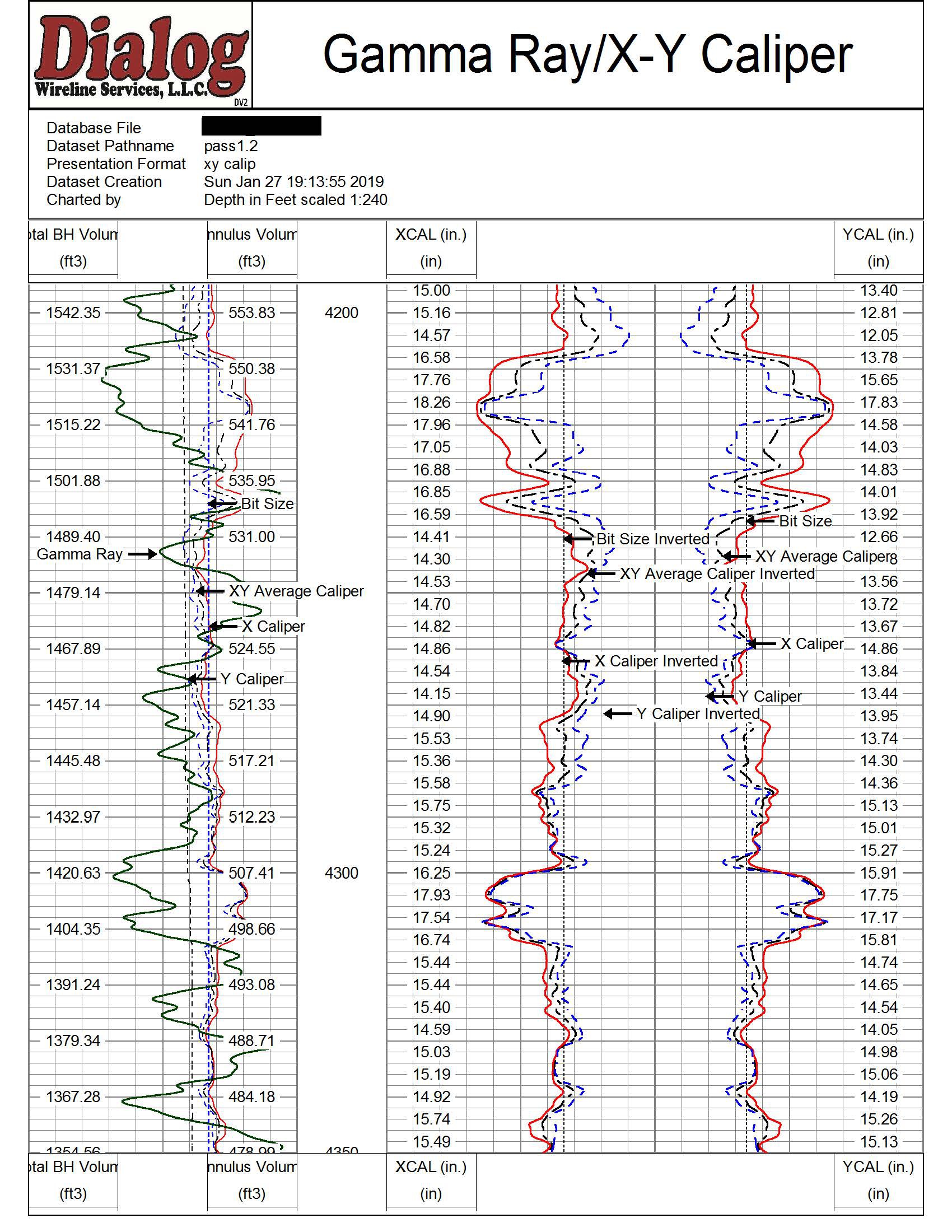

X/Y OPEN HOLE CALIPER