Cased Hole Logging

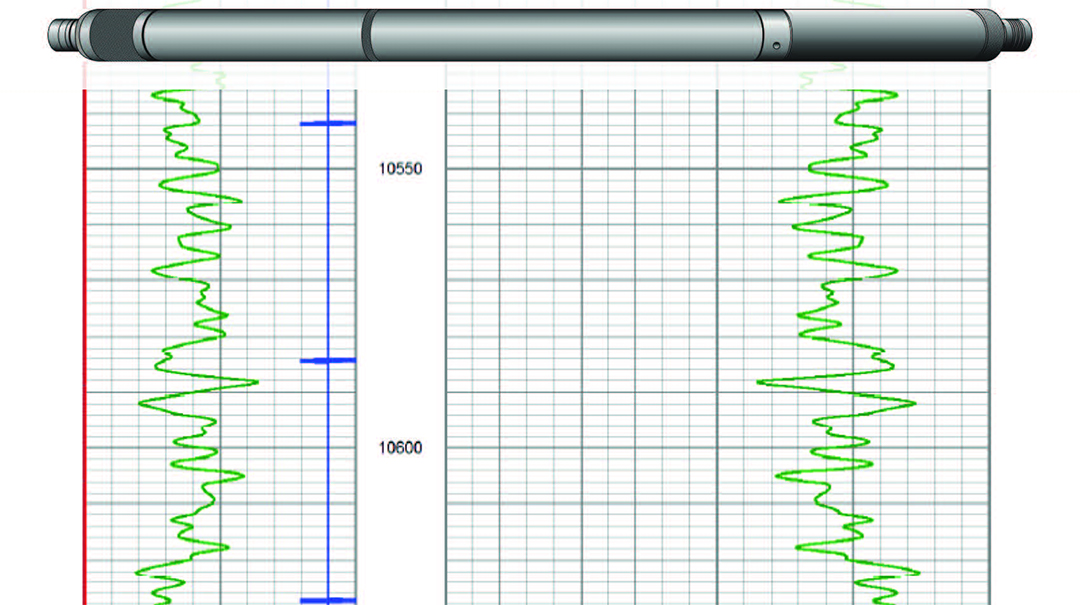

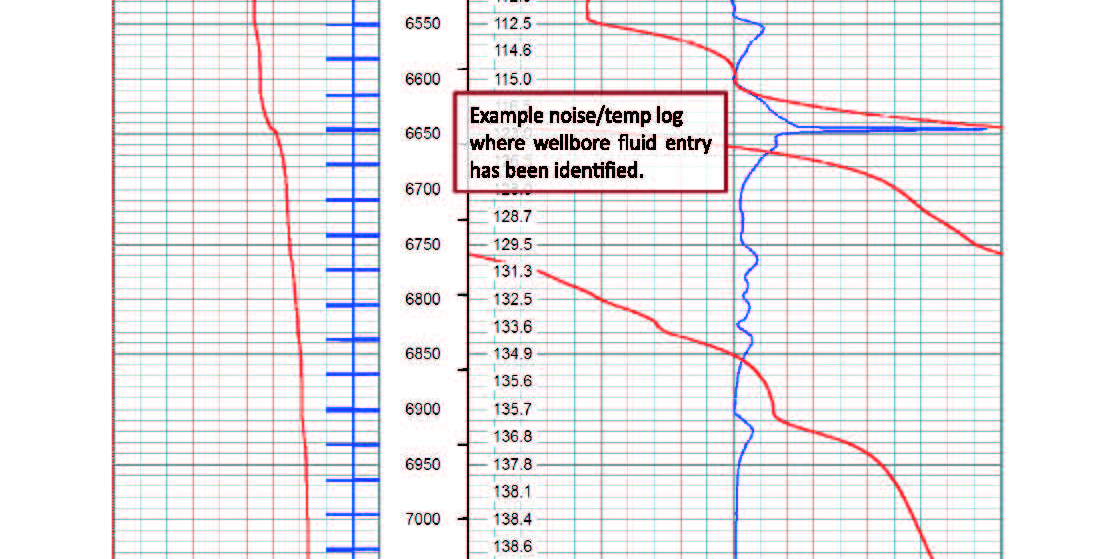

TEMPERATURE LOG

The Dialog temperature log service records a survey of the wellbore temperature. The temperature log service is often run in conjunction with a noise log service.

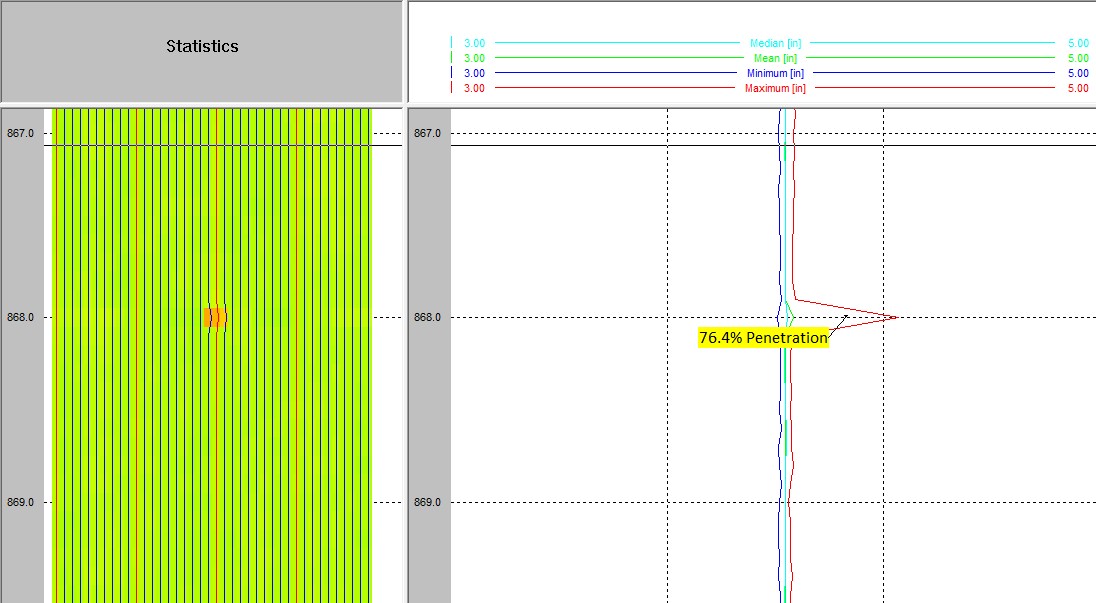

24 Arm Tubing Caliper

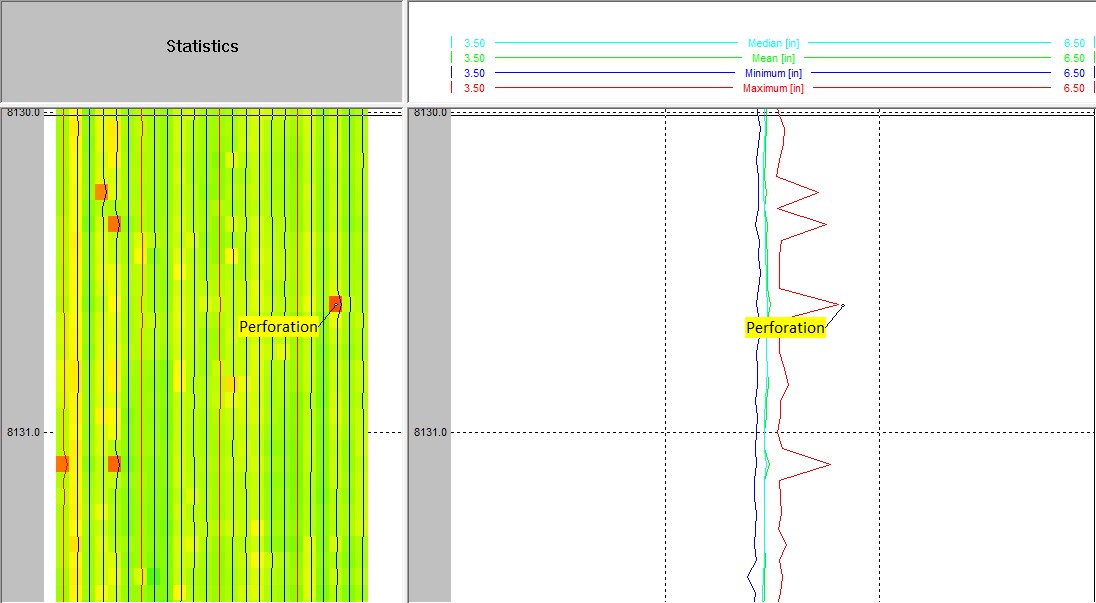

The primary function of the 24-Arm Caliper is to detect the deformation, bending, fracture, perforation, rod wear and inside corrosion of tubing or casing with 24 caliper fingers that are in close contact with the inner wall of the casing. All logging data, including 24-channels of borehole diameter is processed by the computer software, the diagram of borehole inner diameter and a 3-D image of pipe are created to intuitively demonstrate the condition in detail of downhole tubing or casing. This caliper measures pipe ID from 1.77″-7.09″.

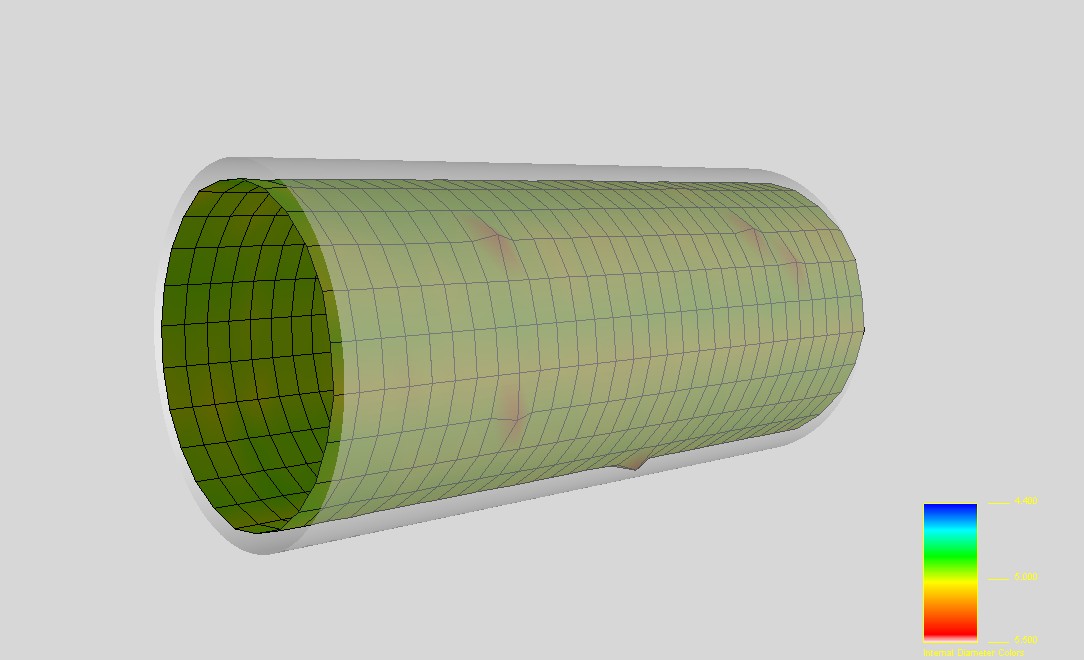

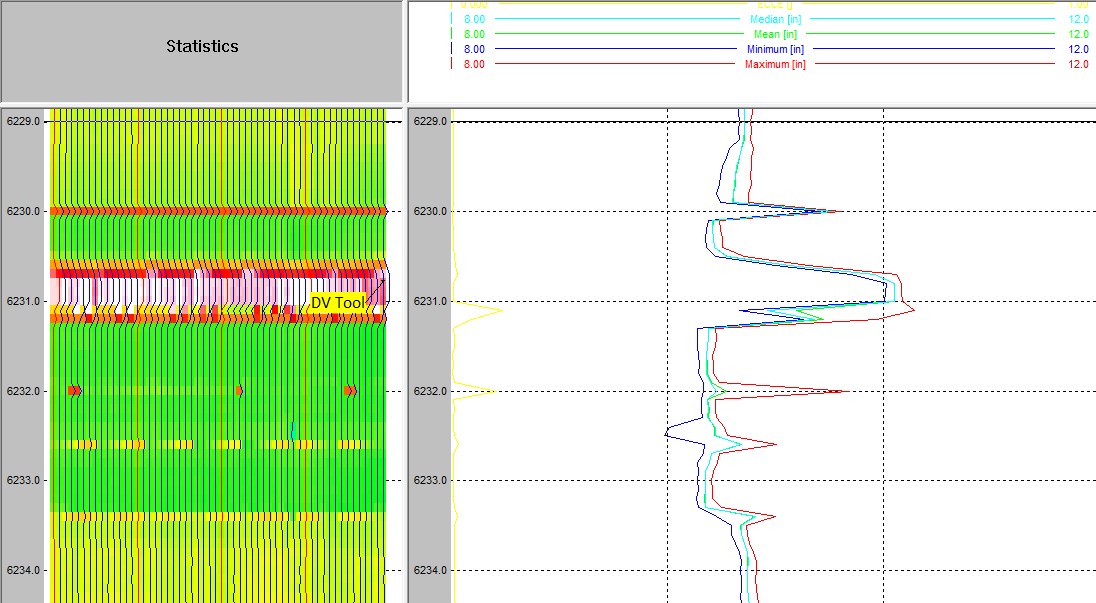

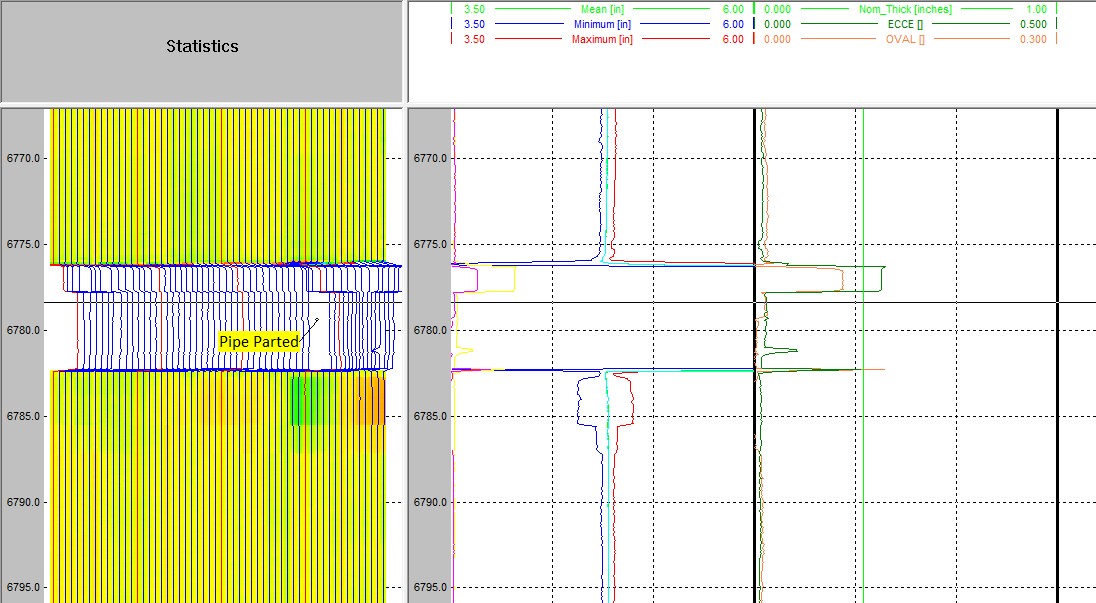

40 Arm Casing Caliper

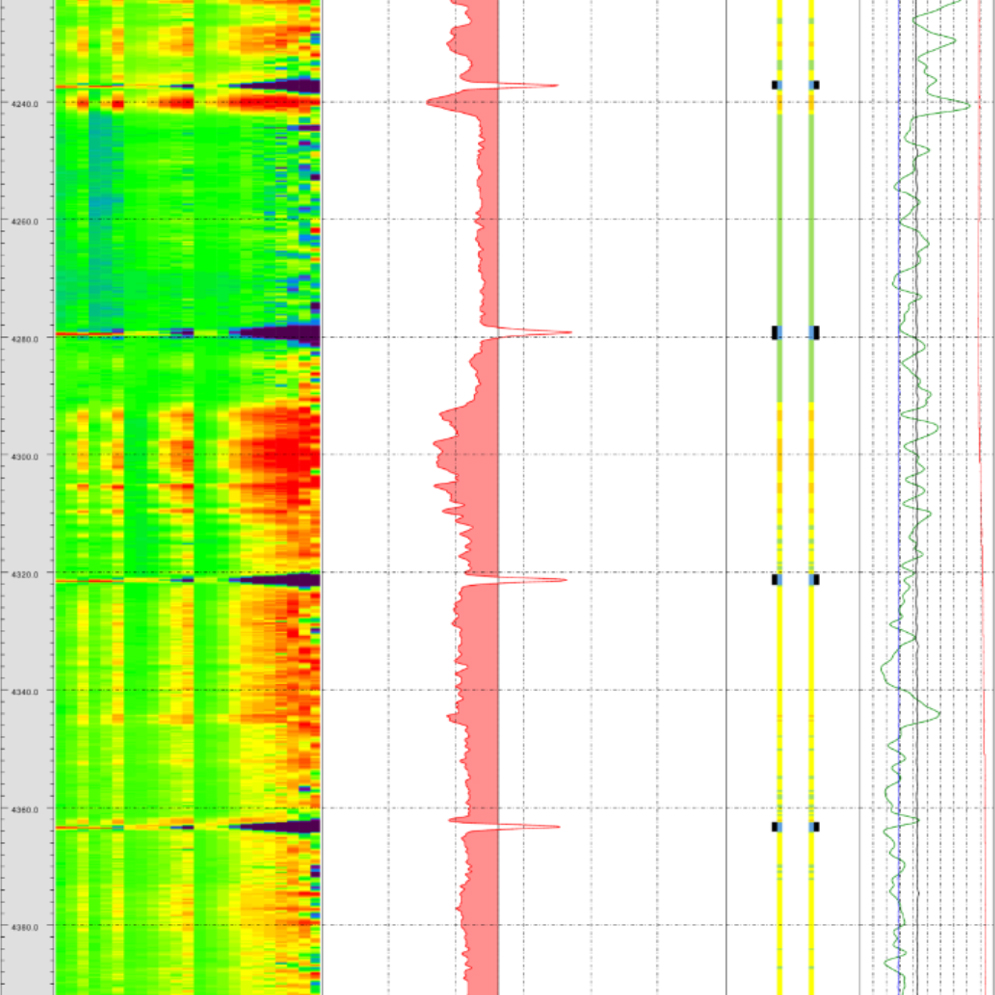

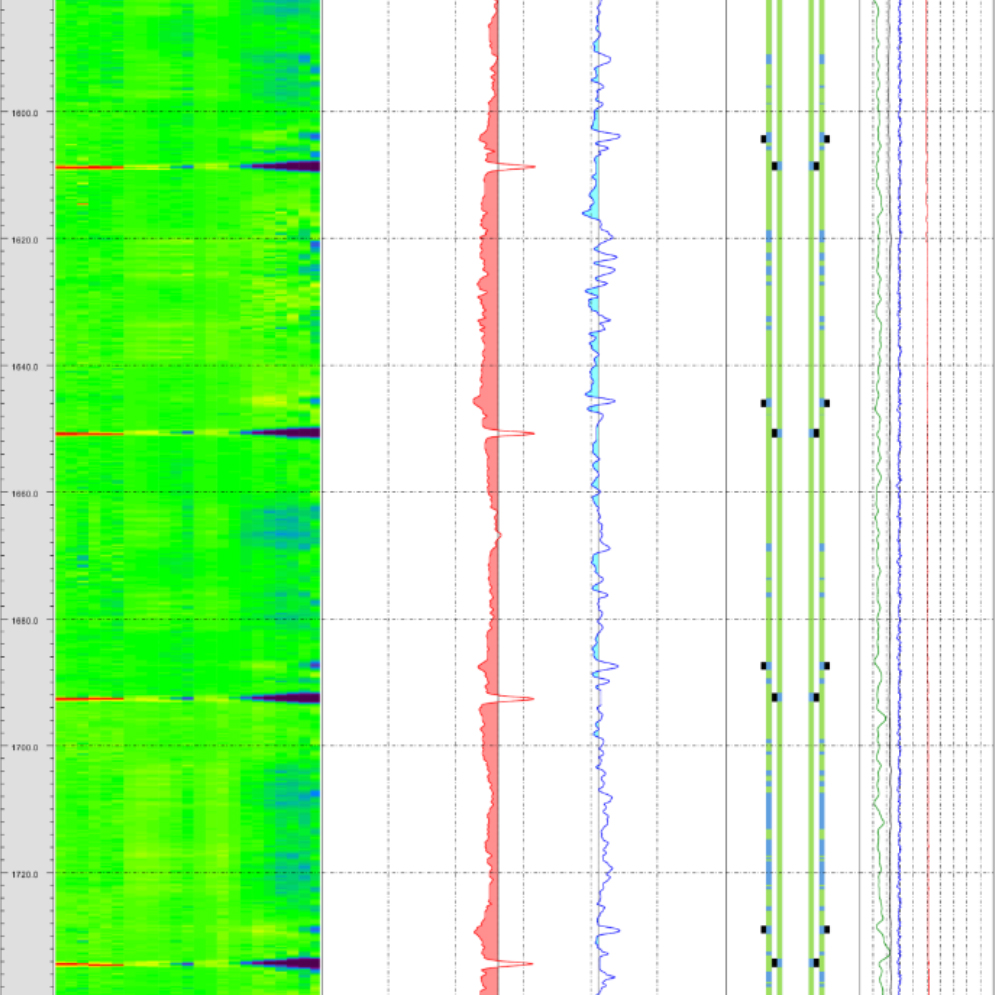

The 40 Arm Caliper is a mechanical downhole well logging tool. The primary function is to detect the deformation, bending, fracture, perforation and inner wall corrosion of casing with caliper fingers that are in close contact with the inner wall of the casing. Each caliper finger is connected to an independent non-contact displacement transducer that features small sizes, long service life, and high measurement accuracy. It measures pipe ID from 3.11” to 8.25”. After data is processed by the computer software, the diagram of borehole inner diameter and a 3-D image of the casing are created to intuitively demonstrate the damage details of downhole casing.

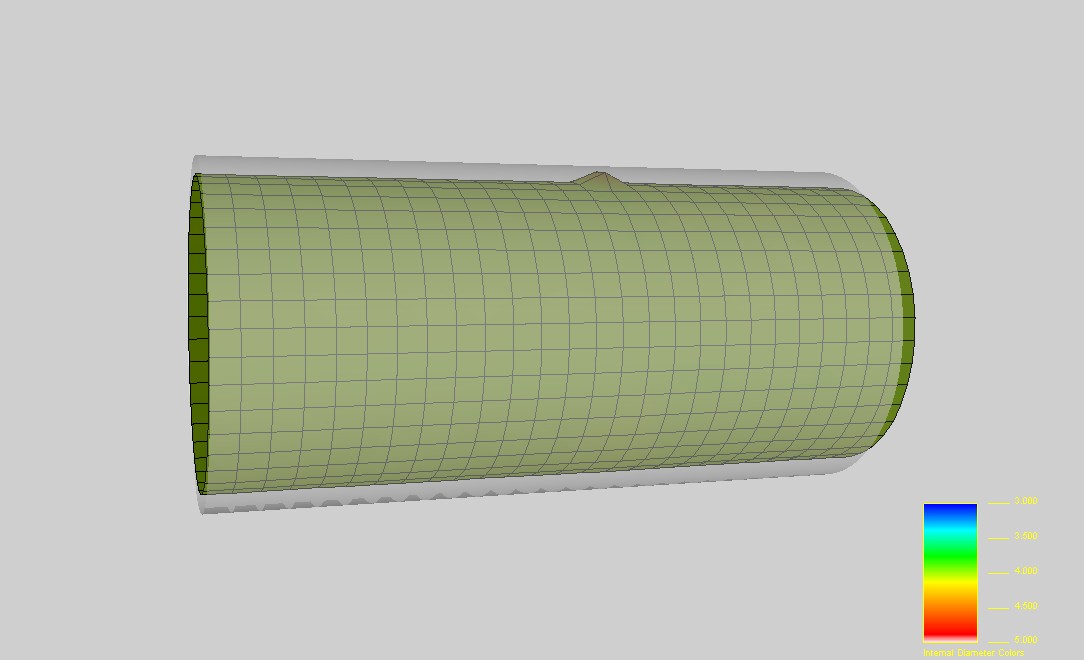

56 Arm Casing Caliper

The 56 Arm Caliper is a mechanical downhole well logging tool. The primary function is to detect the deformation, bending, fracture, perforation and inner wall corrosion of casing with 56 caliper fingers that are in close contact with the inner wall of the casing. Each caliper finger is connected to an independent non-contact displacement transducer that features small sizes, long service life, and high measurement accuracy. It measures pipe ID from 3.94” to 9.625” and out to 13.625” with extended length fingers. After data is processed by the computer software, the diagram of borehole inner diameter and a 3-D image of the casing are created to intuitively demonstrate the damage details of downhole casing.

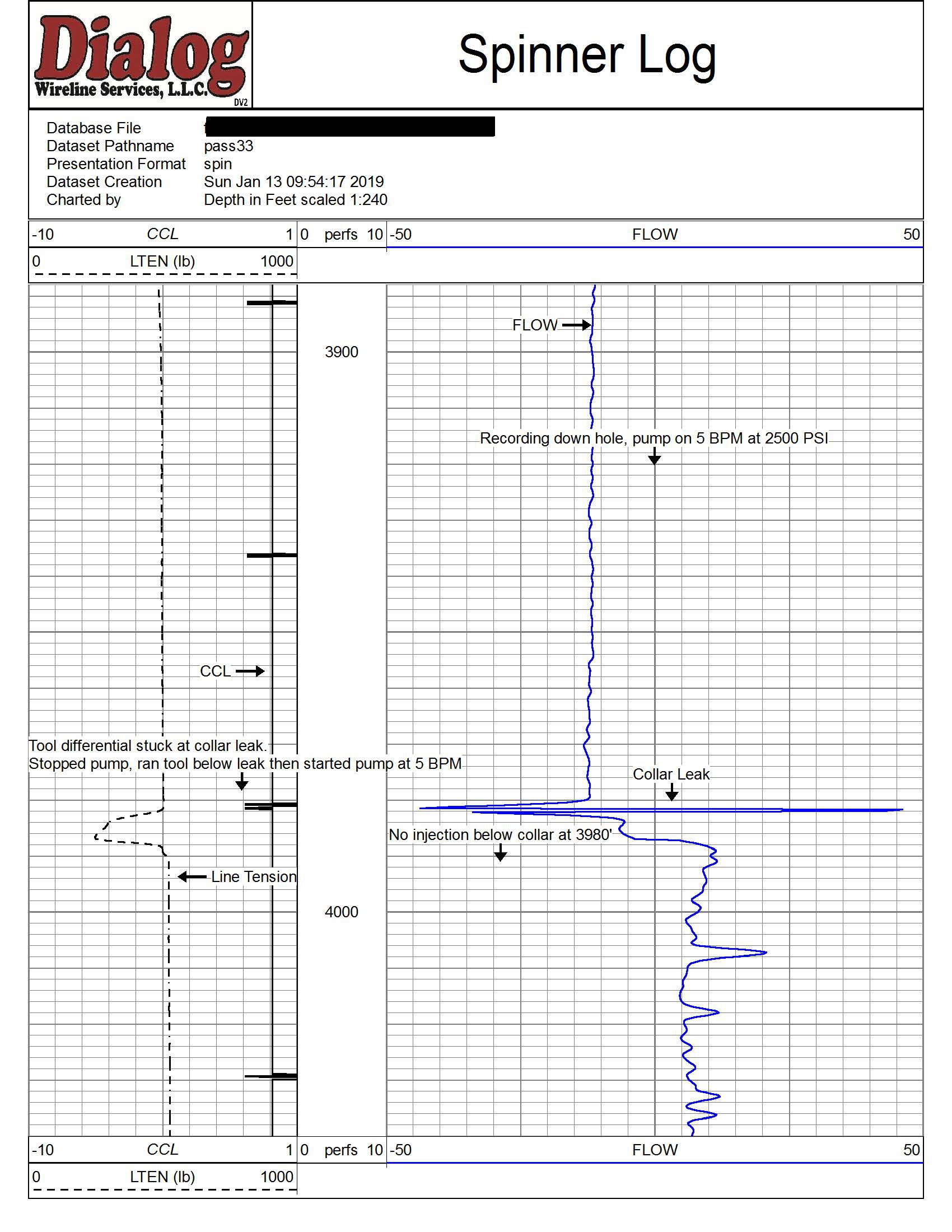

Spinner LOG

Dialog Wireline’s spinner/temperature survey Production Logging Tools measure reservoir performance, identify fluids, and detect leaks in connections or in situations that are too small to detect by caliper tools. This saves an enormous amount of time in lieu of relocating plugs and packers off tubing.

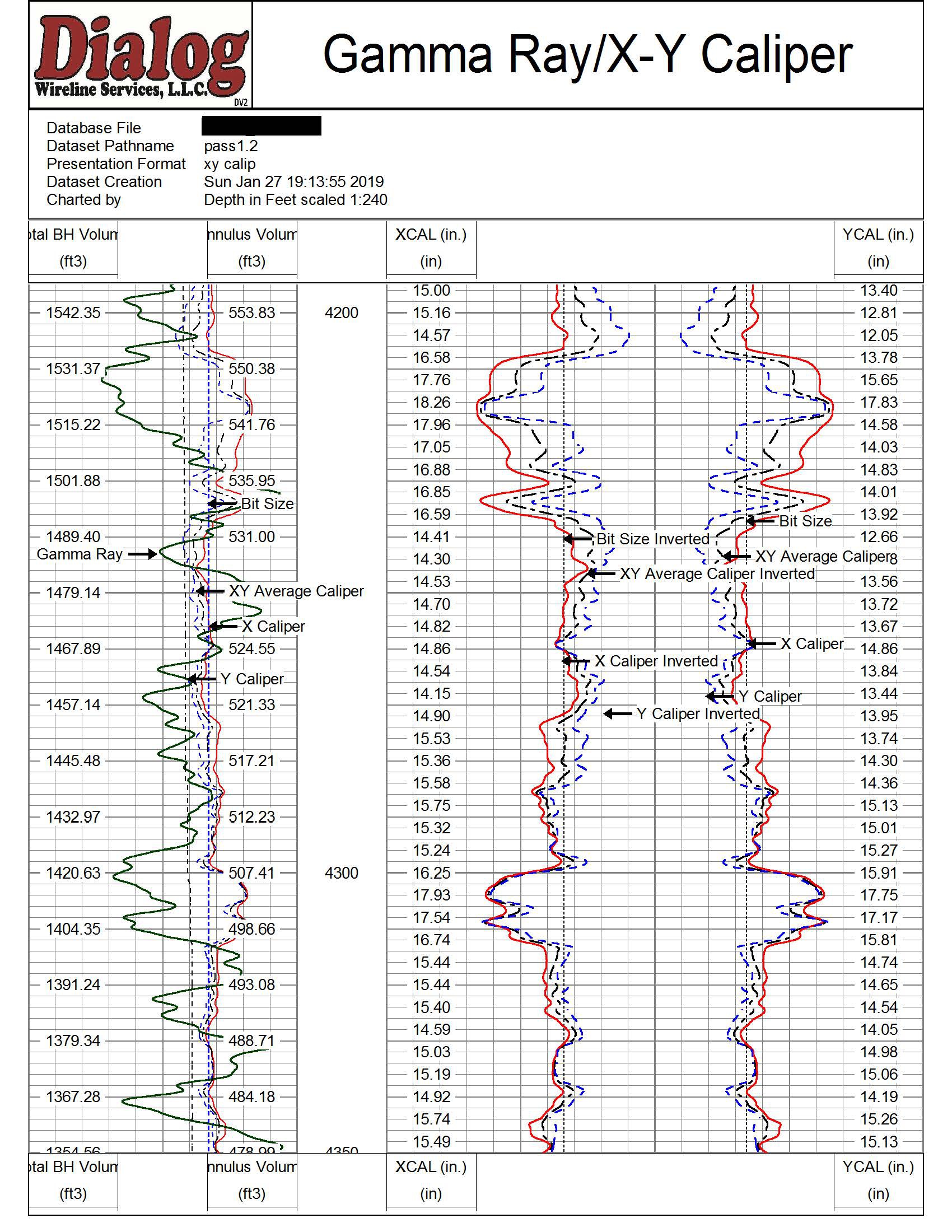

X/Y OPEN HOLE CALIPER

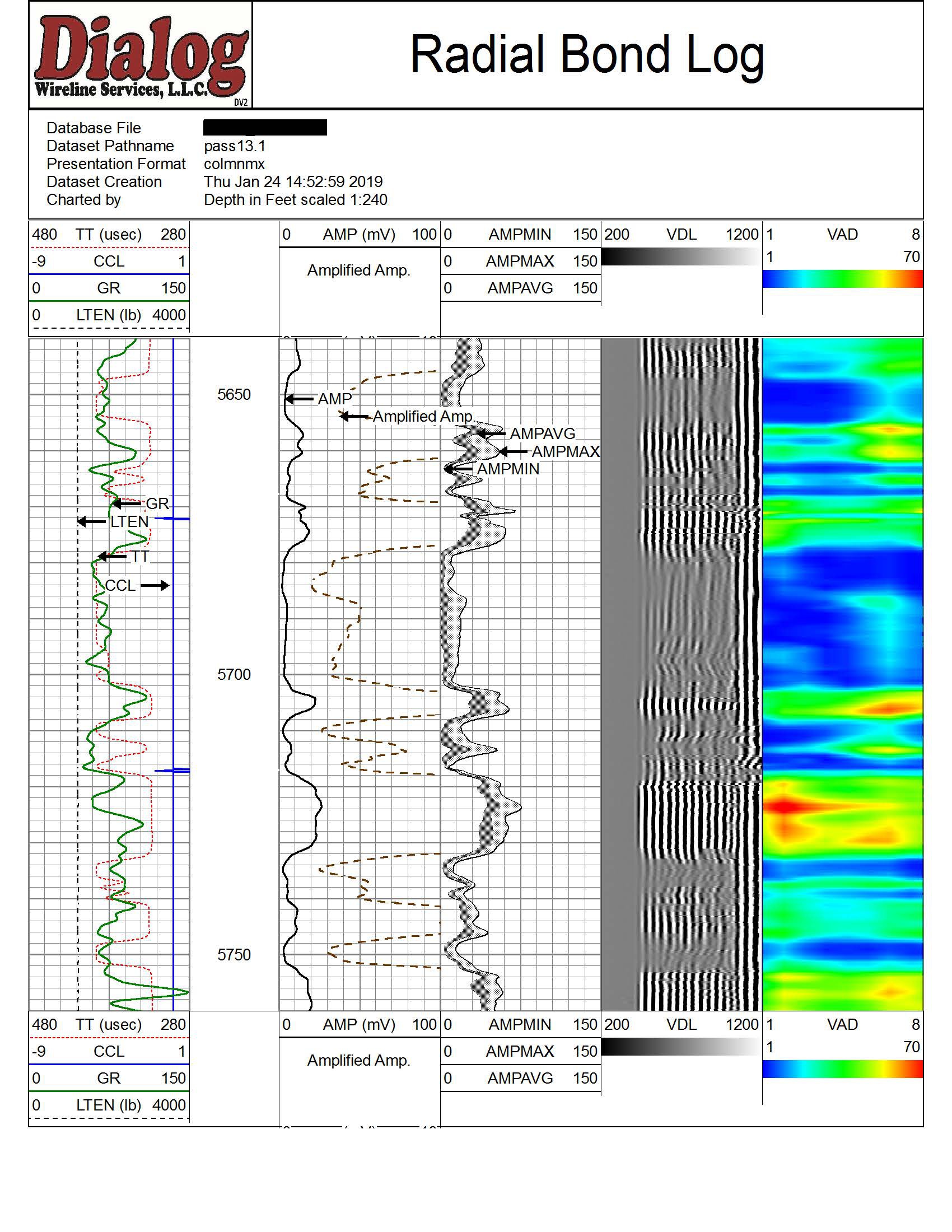

Cement / Radial bond log

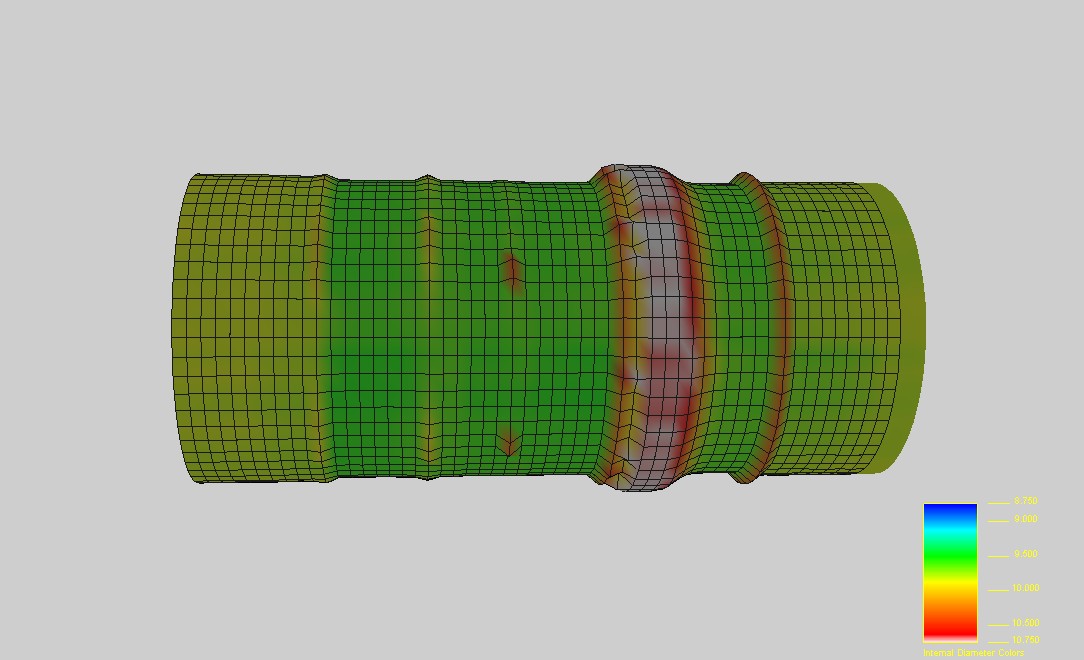

Magnetic Thickness Detector Tool (MTD Tool)

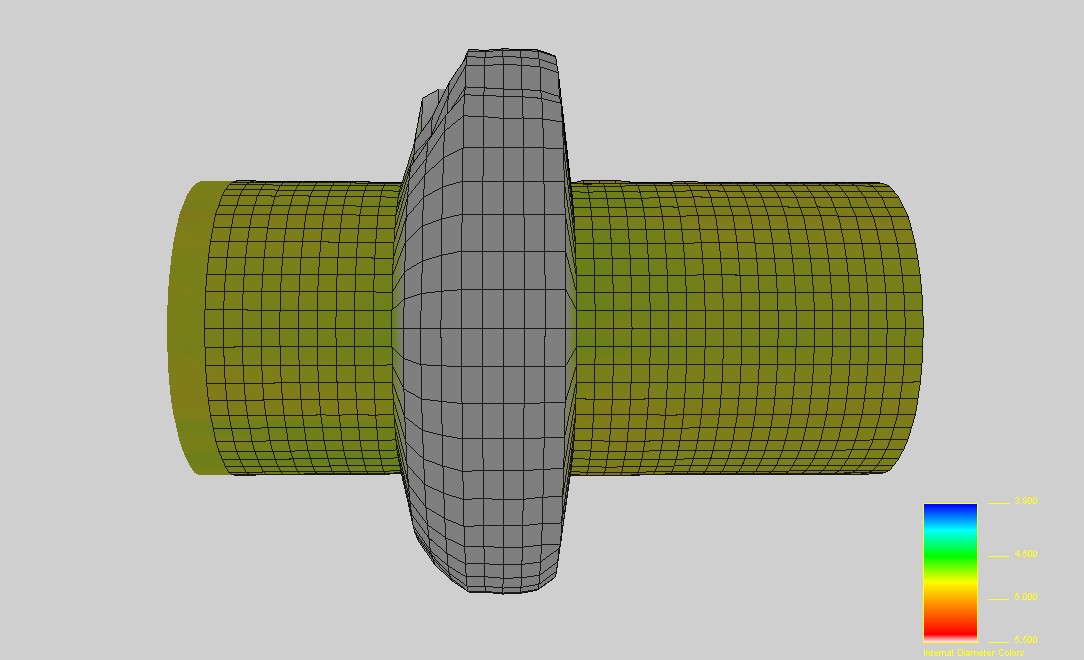

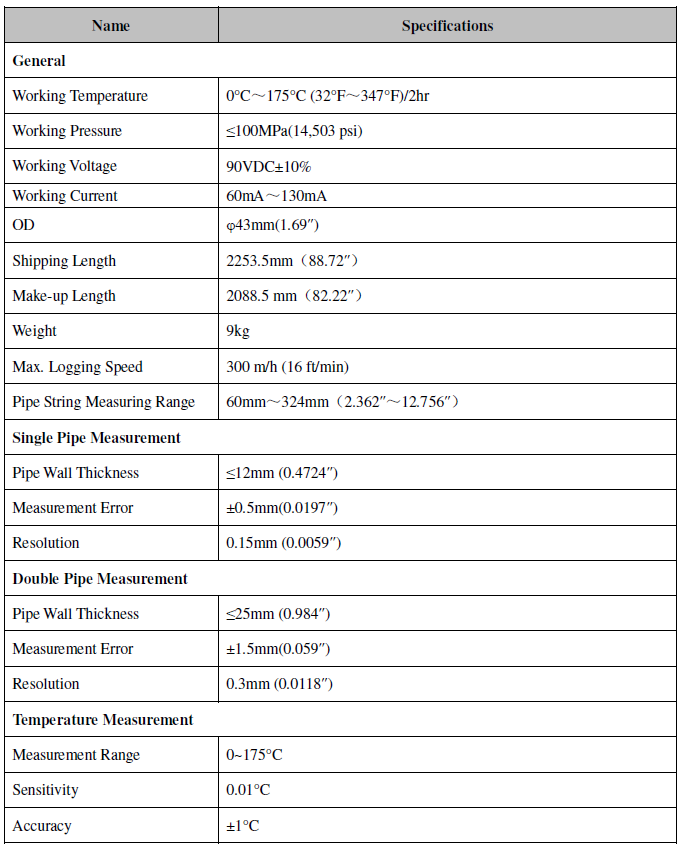

The Magnetic Thickness Detector (MTD) is a 1-11/16 in O.D electromagnetic corrosion measuring instrument primarily run through tubing with the unique ability to simultaneously inspect tubing and the casings behind it. The integrity of the casing string can be evaluated with neither the requirement for costly workover rig, nor the time-consuming removal of the tubing completion. MTD43C-B Magnetic Thickness Detector is a downhole logging instrument which applies the electromagnetic method. It can be used to detect various damages such as corrosion, deformation, crack, fracture, holes in the downhole pipe string, and both the inner and outer metal loss of the double string, to determine the thickness of downhole pipe string, and can correctly reflect the well sketch and the position of the downhole tools (collar, casing shoes, packers and valves, etc.). MTD43C-B Magnetic Thickness Detector can be used for single logging, and also can be connected with GOWell Multi-finger Imaging Caliper product series (24-finger, 40-finger and 56-finger calipers) and Multi-Parameter Logging Instruments to do combination logging